Suddenly are you suffering from this effect in your 3D prints?

It looks like the Pisa Tower, right? The problem worsens on every attempt and it doesn’t look like the X-axis motor losing steps. Each layer displacement is progressive, and looks constant.

You may have searched for a solution and found nothing. Some say to lube your axis, some other says to check and tight your belt tension, which can be dangerous because overtightening it may increase stress on the motor or the bearings and prematurely break them. Moreover, at first glance it may looks like it works, temporarily masking the problem, but soon it will even worsen it as that’s not the cause.

As I couldn’t find any solution on the whole Internet, even after watching a number of YouTube videos and waiting for the ·$%&$%/·$/% Chinese New Year to get a reply from AnyCubic’s Customer Service (it’s amazing how these people can go on holidays for entire weeks without providing some kind of “back up”, “emergency” service; that doesn’t happen even in Spain! They simply stop 100% any sort of activity… unbelievable!), I was about to buy (it’s not expensive; merely about 10 € from a local store) a new step motor and mess trying to replace it. Luckily I didn’t, as per AnyCubic’s themselves recommendation (not to attempt such an operation until you’ve tried absolutely everything else).

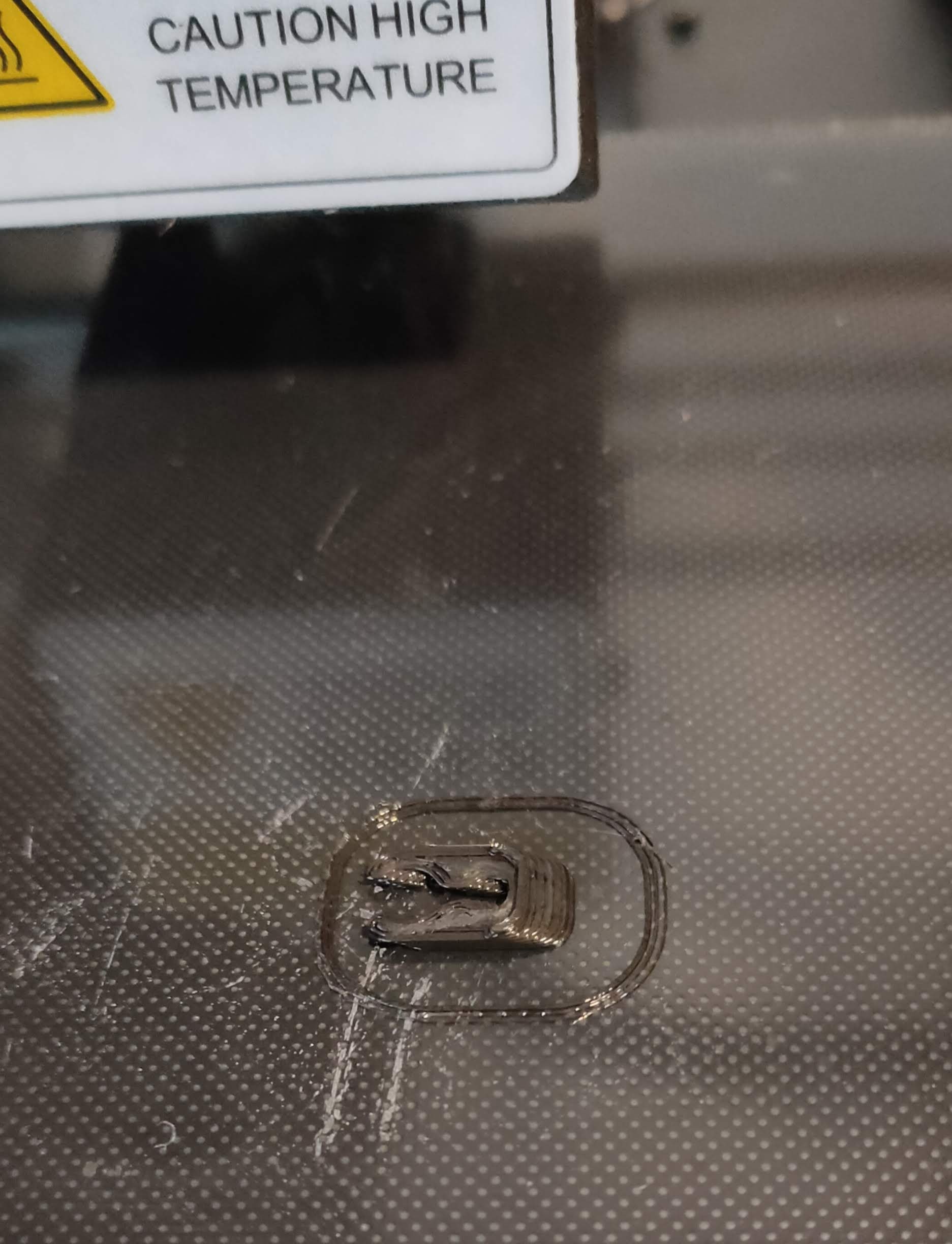

But after watching one German video and translating the comments, which was not the same problem but somehow related (a “click-click-click” sound when the X-axis was moving), one user gave a hint and the bulb lightened. The pulley where the belt is attached to could be loose and that would be the cause of the sound, hitting the metal bar on each movement.

That could be consistent with the vertical layer decoupling and the belt tightening temporarely improving it to just worsen it later – as you apply more tension, the pulley getting even looser after that.

The solution was as simple and straight as tightening the screw with the proper (thin) allen wrench that came with the printer itself. After putting it inside the hole and noticing that, in fact, it was loose, it became clear that was the cause of the problem.

And that’s it. After that, perfectly straight prints!

Who knows how many people may have embraced in changing motors, pulleys, belts or bearings and may have attributted the cause of the problem to that, while it could be that they sported this same simple issue…

Bottom line: always check that your screws are tightened!